RotoEdge Pro Improves Rotomolder

Revenue

Challenges

Real-Time Info, Automated Scheduling, Machine Planning, Detailed Productivity Updates and Order Info.

RotoEdge Pro helps manufacturers move from manual spreadsheets and sticky notes to streamlined, actionable plant and machine scheduling, real-time detailed productivity updates, and customer order information.

Running a manufacturing machine with multiple arms can be stressful and mistakes can be costly, leading to late shipments and frustrated customers. With more than one machine or multiple plants, problems can multiply many times over. But now there is an answer- RotoEdge Pro is the solution that brings control to the chaos you are feeling.

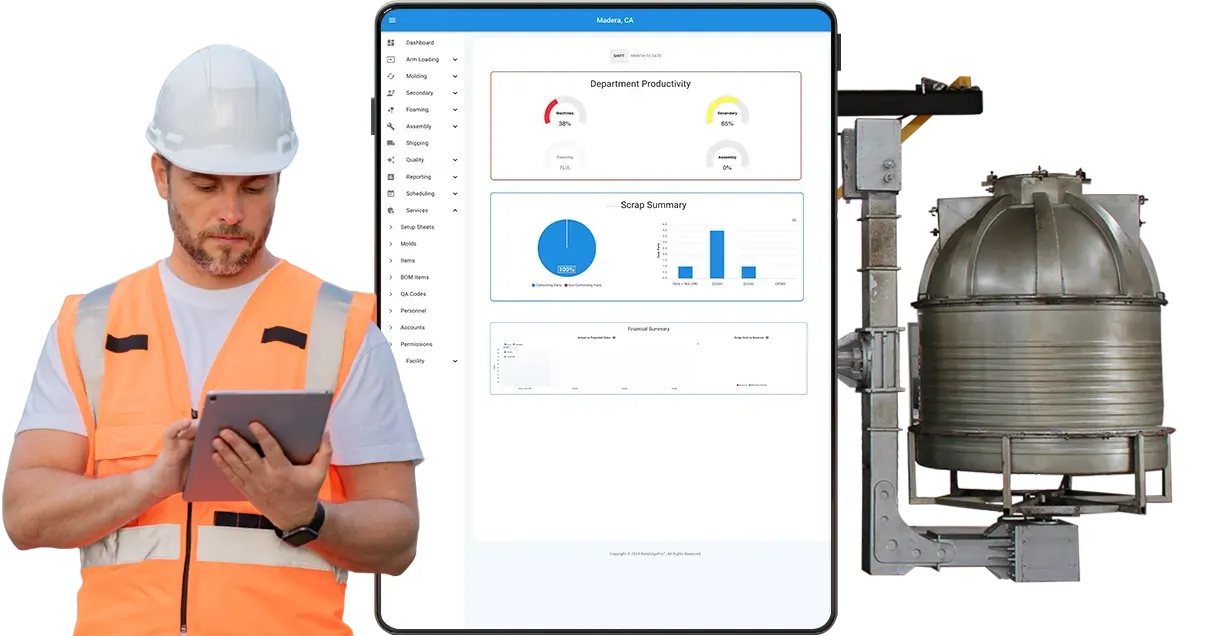

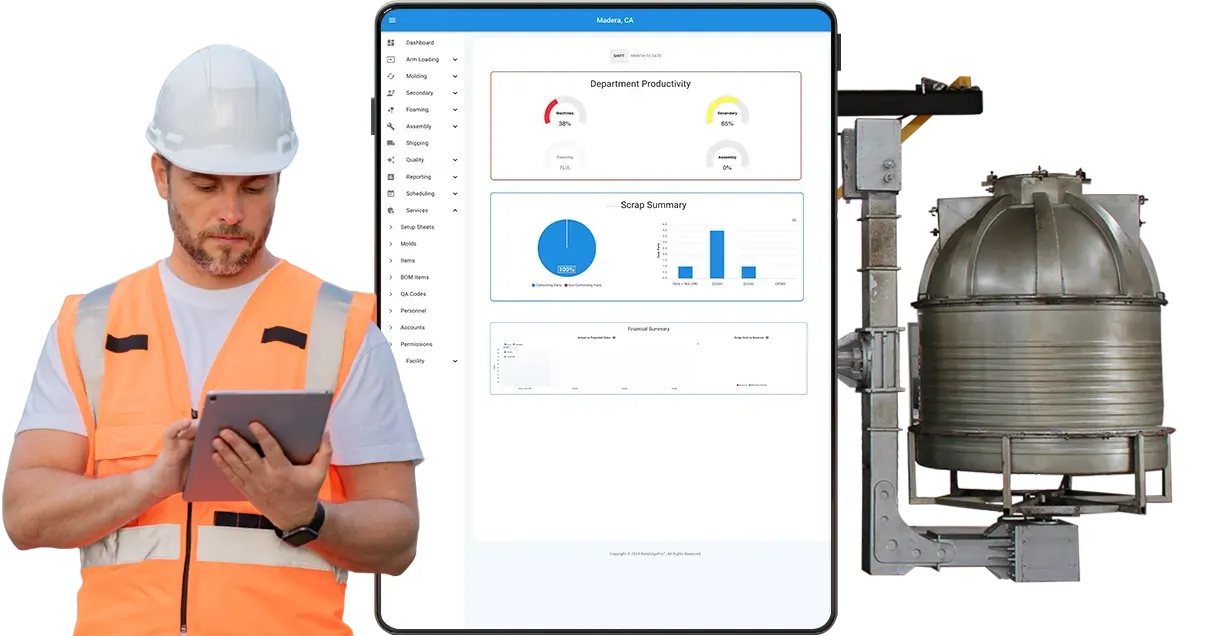

RotoEdge Pro is a scheduling and production control application that solves complex manufacturing challenges. RotoEdge Pro software solves the problems of paper-based manufacturing scheduling, order tracking, change orders and updates. With RotoEdge Pro, operations managers can digitally track machine productivity, available capacity, non-conforming or scrap product, trends and order status, as well as employee performance – all in real-time.

The RotoEdge Pro Dashboard delivers instant visibility into margins, production rates, and scrap metrics. Strategically deploy your personnel to high-margin projects to maximize both efficiency and revenue.

RotoEdge Pro solves manufacturing scheduling challenges and the chaos around the machines, inventory, order status, and operators questions. Now, machine operators can be part of the success: real-time digital info lets them work faster and more efficiently. Operators now know which molds, resins, and accessories to use when and where.

Standard ERP and accounting applications weren’t built for the unique demands of rotational molding. They often lack the specialized tools needed to handle complex scheduling, resin requirements, scrap management, and labor productivity. Until now, there has never been a production system that combines ease of use with a rapid implementation designed specifically for the rotomolding industry.

Gain instant access to live and historical data across your entire facility. RotoEdge Pro’s advanced tracking tools provide a clear view of your business, from department-level financials down to individual personnel output.

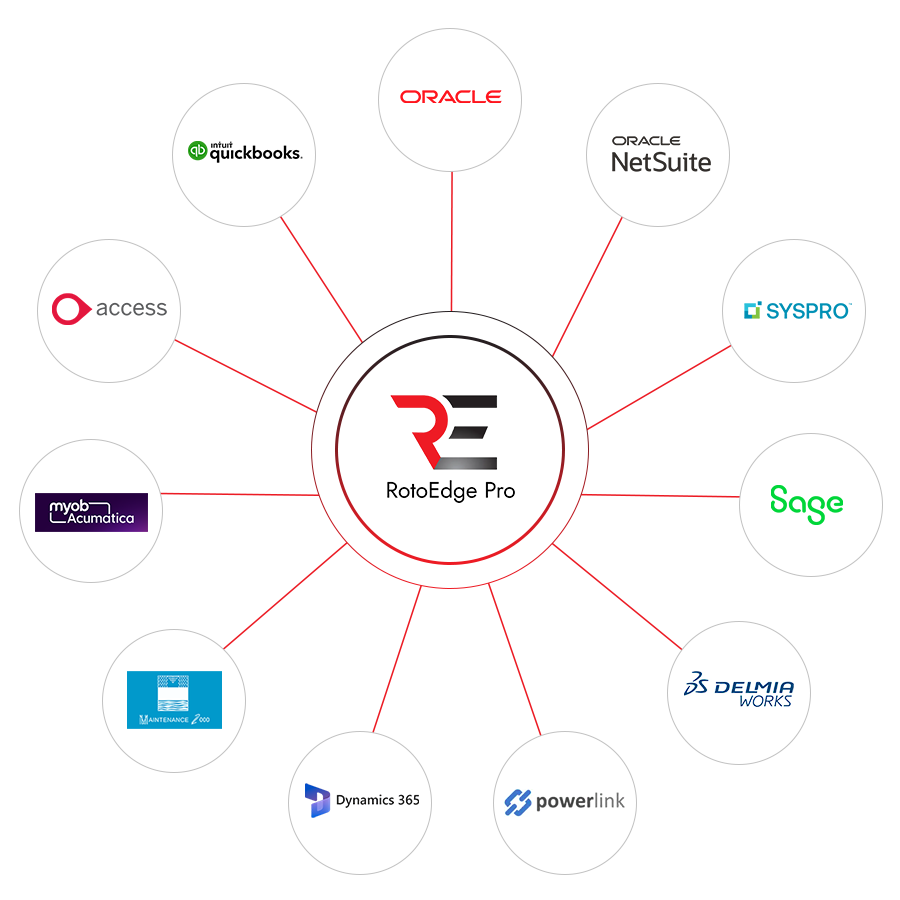

RotoEdge Pro is specifically designed and built for rotational molding operations that want to track machine output and still use their existing accounting and ERP systems.

Skip the months of setup. RotoEdge Pro is designed for rapid deployment, allowing you to begin tracking productivity, scrap, and revenue across your entire facility in just days.

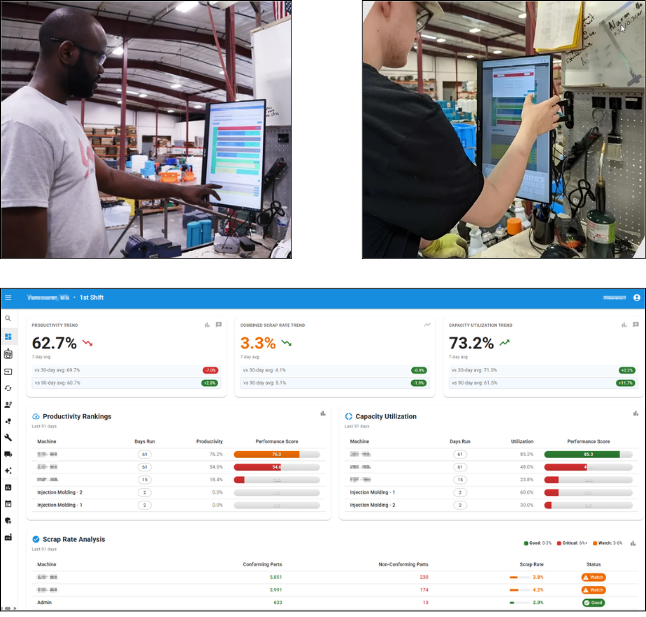

Empower your team with an intuitive touchscreen interface for seamless login and real-time tracking. Analyze comprehensive metrics across shifts, personnel, and machine output to identify training opportunities and optimize performance for every machine arm.

RotoEdge Pro optimizes your operations by pinpointing specific training needs and productivity gaps. From machine output to scrap reduction, get the data-driven insights you need to overcome manufacturing challenges and scale your production.

RotoEdge Pro was designed for production teams to easily increase awareness and productivity. No more management walking around the plant to see whether a job is underway.

Drive a culture of excellence by giving production members the tools to monitor their own run rates. When workers can track their productivity, efficiency, and job progress in real time, they take ownership of their output—and can be fairly rewarded for their performance.

Have questions about how RotoEdge Pro can solve your Rotomolding Scheduling and Productivity Challenges?